|

With over 110 employees, and 2 shifts 24 hours operation, we have the capabilities and management experience to ensure your project is executed right. We are an all-in-one facility that can handle production, assembly, packaging, warehousing, and shipping.

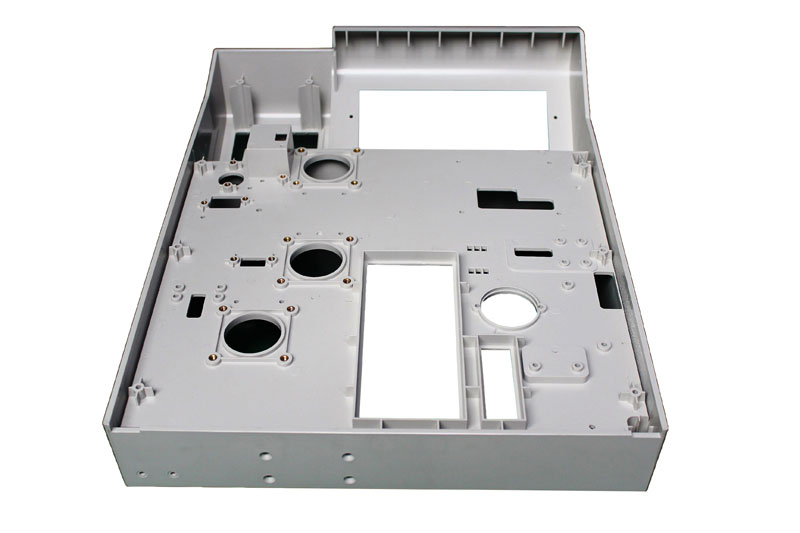

JQ Plastic Mold has a dedicated assembly division that can handle complex assembly of any product and manage customer consigned inventory of subcomponents. Our partners simply expect a turnkey, worry-free solution to their projects.

Our tooling department can perform fabrication, routine maintenance, and repair of your molds to prevent unexpected production downtime. Our innovative automation-equipped manufacturing work-cells decrease per-unit costs and consistency of production.

Finally our lean manufacturing and logistics programs eliminate many value-added expenses, allowing us to deliver products for a lower overall landed cost than major sources of injection mold and molding around the world and even domestic China.

12 Injection molding presses ranging from 80-600 tons of pressure 12 Injection molding presses ranging from 80-600 tons of pressure- 24 hours 2 shifts operation

- Full logistical management with direct shipping

- Lean manufacturing with just-in-time and Kanban practices

- Tooling maintainance and fabrication

|